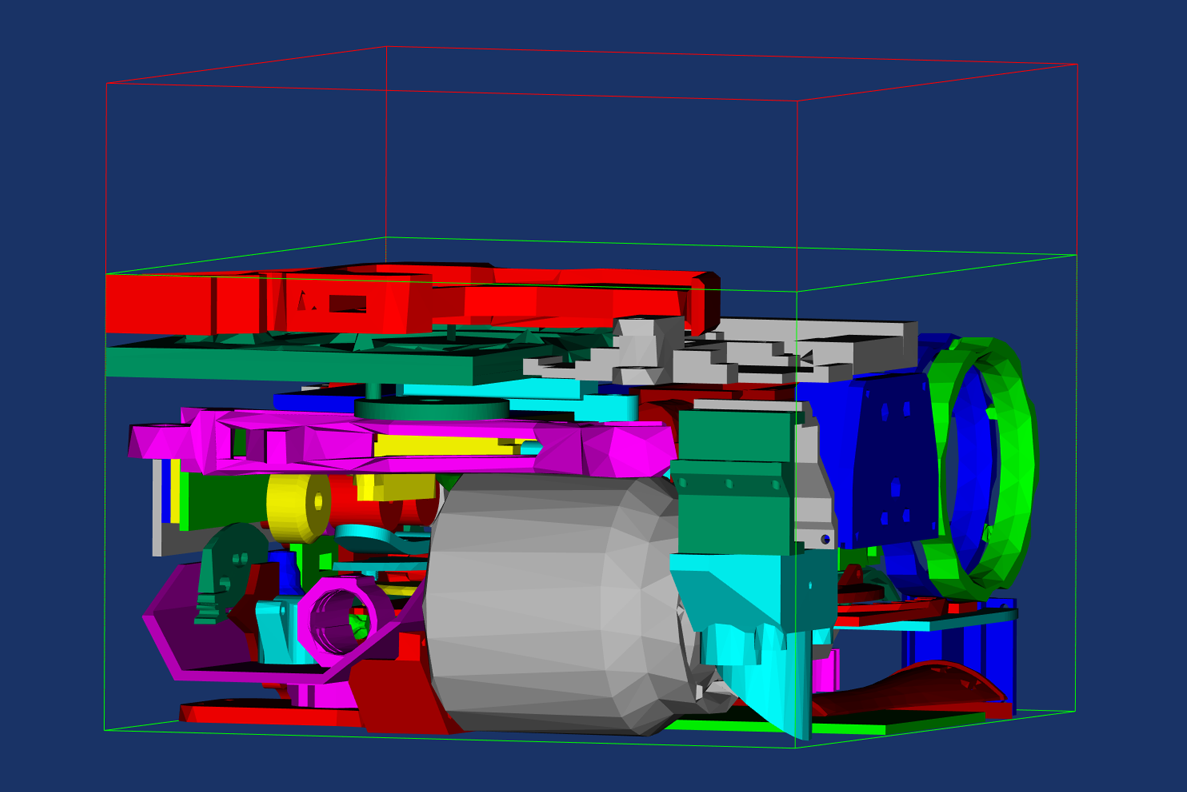

The solution of cutting and packing problems plays an important role in various industrial branches. SCAI can offer long-term expertise in applying discrete methods to two- and three-dimensional arrangement problems. Not committed to a specific algorithmic paradigm, the focus of our projects is on the efficient solution of industrial problem instances, considering and exploiting the special problem structures. Application areas include leather and textile manufacturing industry (NESTING), VLSI physical design of integrated circuits (ROUTING), and packaging problems in the automotive industry (3D-PACK).

Another field of research focused on by SCAI is machine allocation. In many industries there is a great potential of optimization in this regard, e.g. in the automotive industry and other lines of production manufacturing in series.