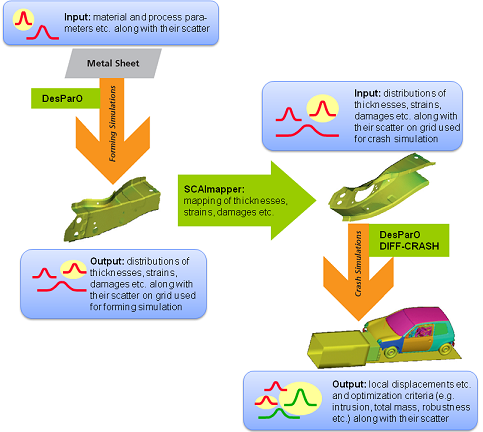

Products are often manufactured by means of a sequential chain of processing steps. As a minimum, the most important process steps and corresponding variations should be analyzed in order to obtain realistic information about relevant parameter dependencies and properties of the overall process and resulting products.

The patented PRO-CHAIN methodology helps to

- quantify influences of scatter from the entire history of a process up to the ultimate result, giving valuable insight into local behavior,

- considerably improve the forecasting quality of simulations and, with a subsequent robust optimization, the quality of the resulting product,

- answer and visualize »what-if« scenarios, without additional time-consuming simulation runs.

PRO-CHAIN can be applied, for example, to the following process chains:

- from metal forming / casting to component tests / crash analysis

- from semiconductor process over device to circuit simulation