User benefits

Everybody involved in computer-aided engineering (CAE) has to deal with numerous designs that vary in geometry, material, and boundary conditions. ModelCompare is a quick-look tool capable of determining the differences between two FE models, which are discretized similarly. With ModelCompare, you can quickly compare two FE models within the visualization tool used without going through the burden of manually determining the differences. A report can be generated to document the changes.

Our contribution

At Fraunhofer SCAI, we thrive at the cross-roads of mathematics and data analysis. This enables us to provide cutting-edge tools that address the everyday needs of CAE engineers. They often need to compare and identify parts from different models when they analyze different simulation results. Therefore we developed this tool as one step of an overall simulation data analysis workflow.

A seamless interface as a plug-in

ModelCompare is available as a plug-in for GNS Animator and can also be provided as a seamless, versatile interface for the visualization tool of your choice or as a stand-alone tool.

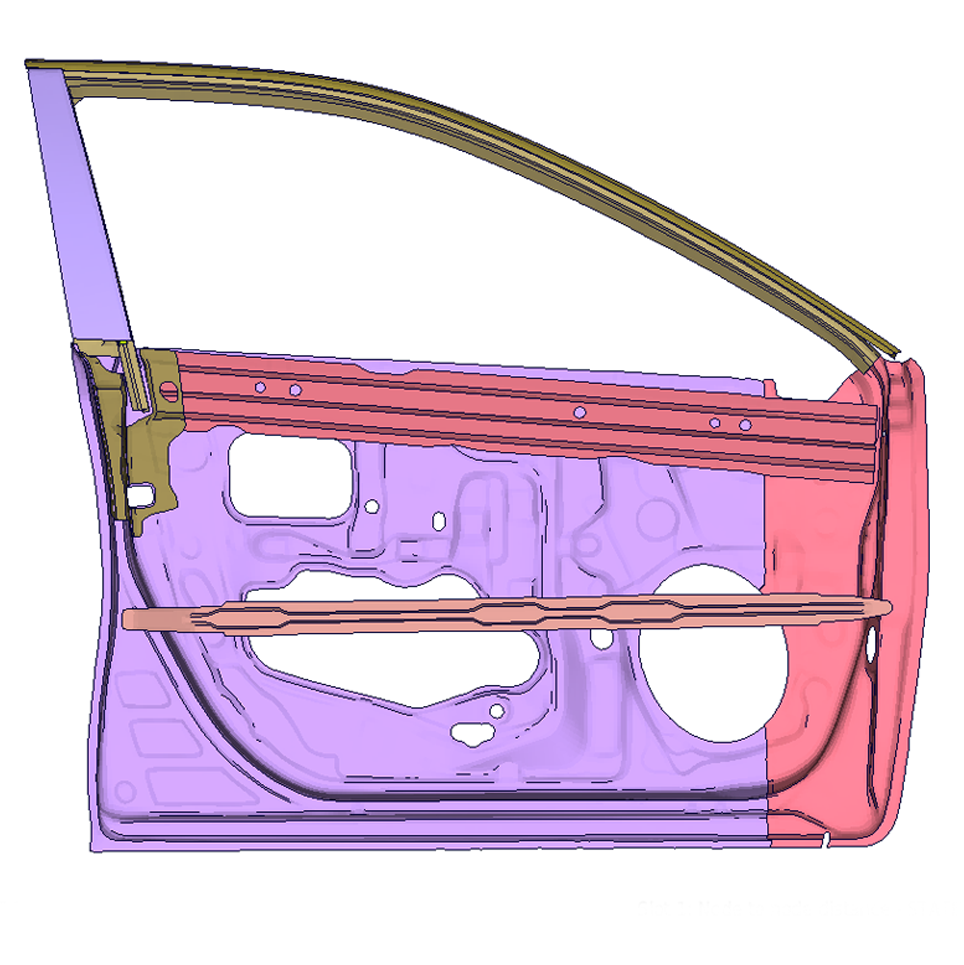

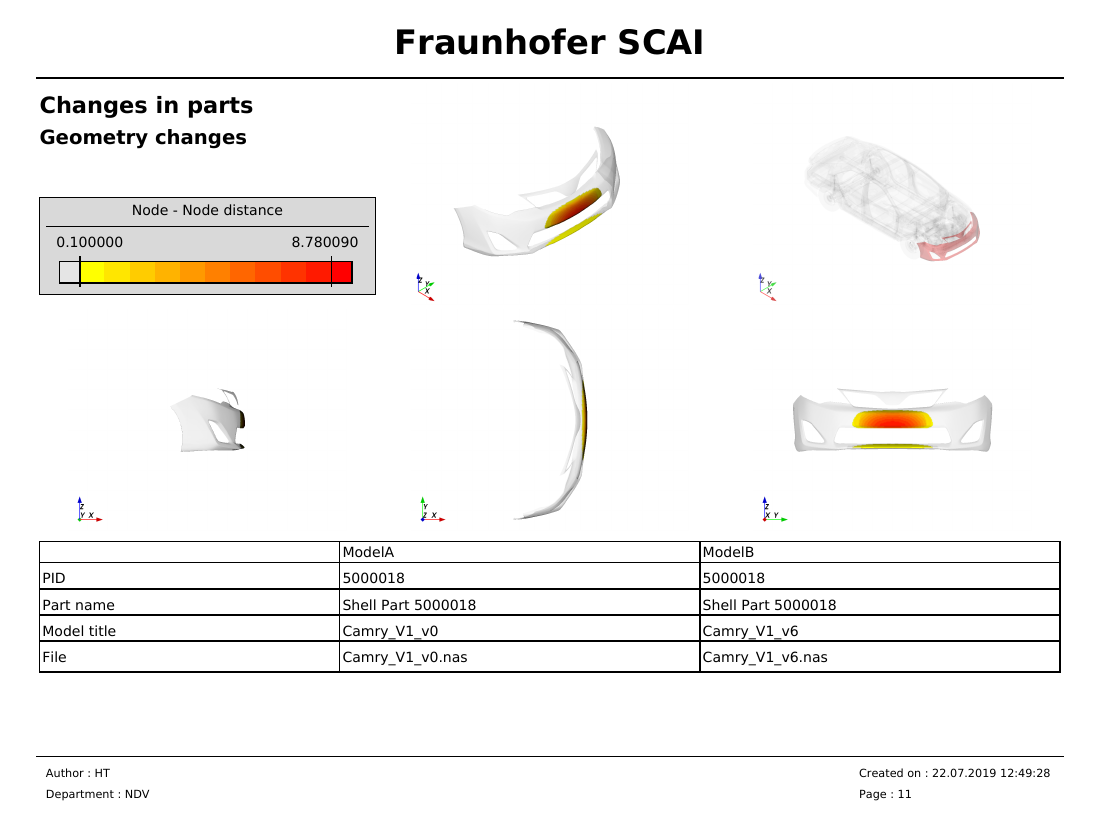

Geometry and mesh changes

Accurate estimation and depiction of the differences in the geometry of two FE models are made based on their nodal positions. Additionally, parts with the same shape but different mesh configurations are detected and displayed.

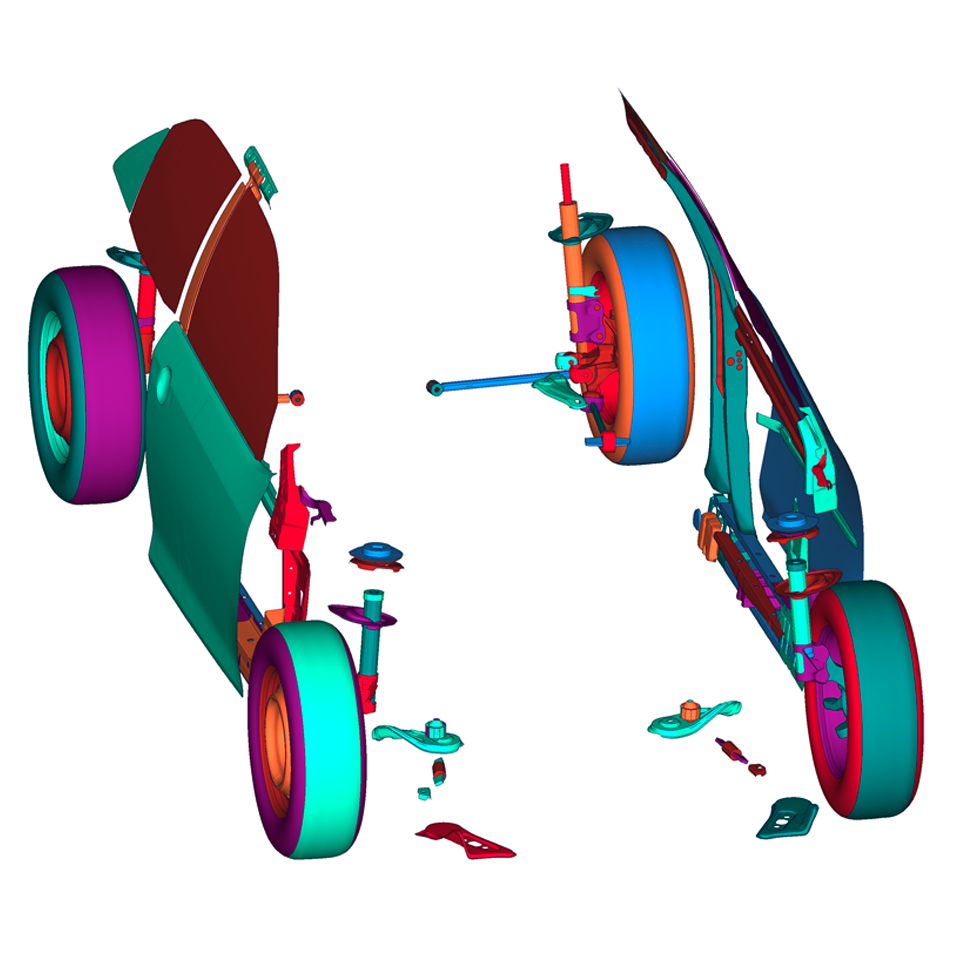

Duplicated parts in one model

Parts with the same shape and mesh, which occur several times in a model, are identified independently of their orientation.

Multi-parts detection

ModelCompare identifies a part in the first model that is split into many parts in the second model as a set consisting of these parts.

New and missing parts/elements

New parts that have been added to or parts that have been removed from the model are detected and visualized. Elements missing in a part in one model, e.g., due to improper meshing, are also detected. The tool also detects if an element belongs to two different parts in the two models.

Material-ID, thickness, or function changes

Differences in material-ID, thickness, or user-specified function values between both models are detected. Here, thickness changes can be part-based or element-based, while function values can come from nodes or elements.

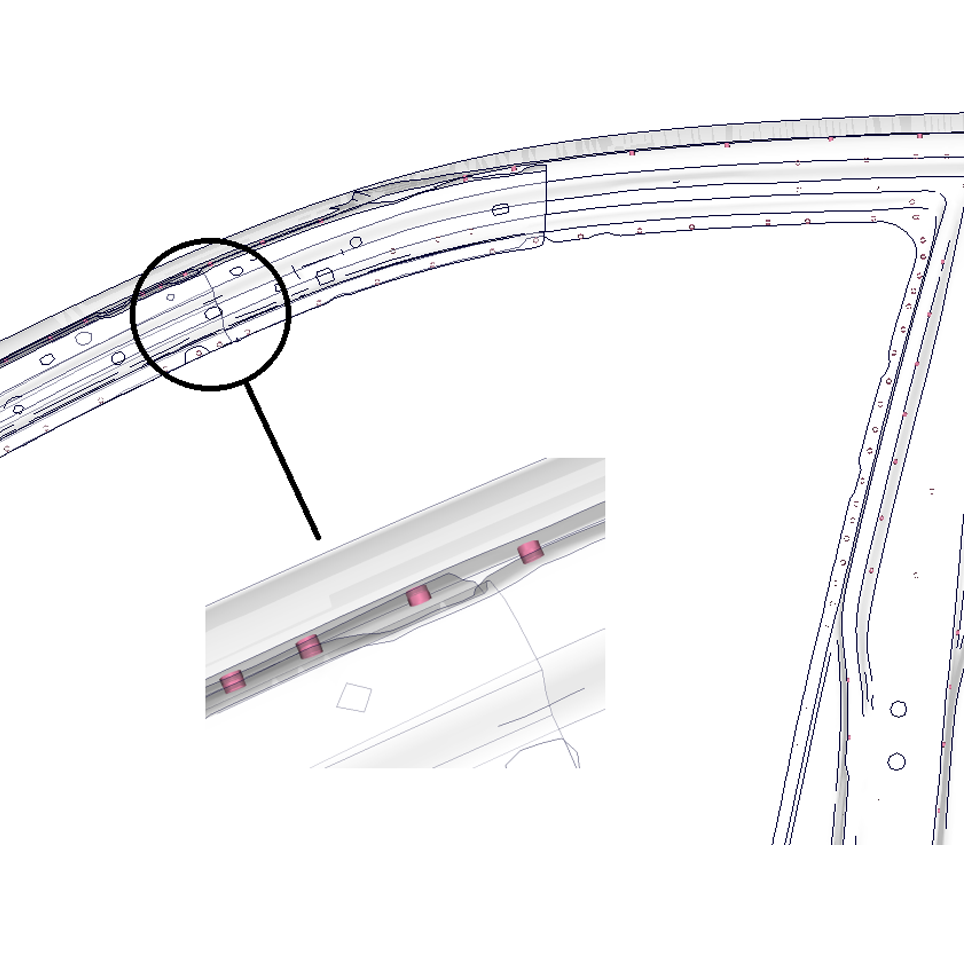

Detection of changes in spotweld, RBEs, and adhesives

Differences in the attributes of the spot welds (e.g., part identifiers, element identifiers, connected parts) along with new, missing, and moved spot welds are identified and visualized. ModelCompare can also determine the differences in the positions of the master and slave nodes of the rigid body elements (RBEs). Hexa element-based adhesives can be identified, and changes such as added, deleted, and moved adhesives can be detected.

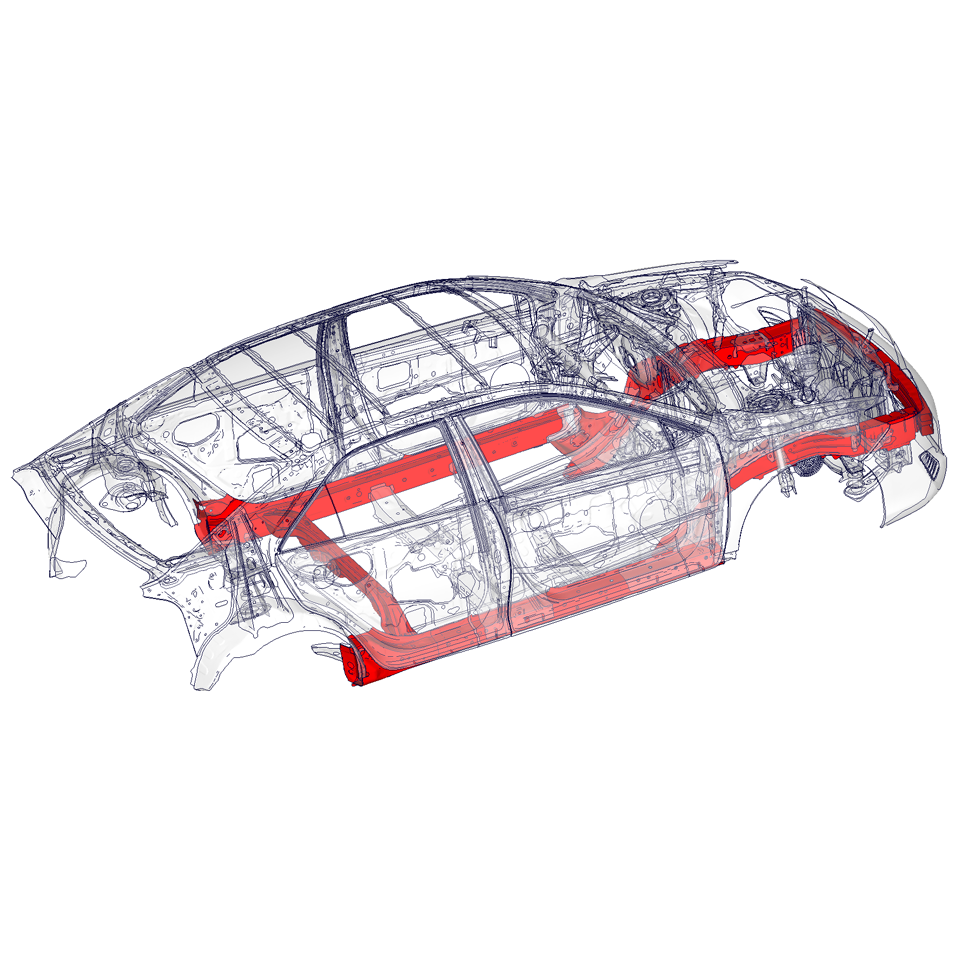

Reporting functionality

A PDF report can be generated during the comparison process. The report displays all parts with changes in geometry. These changes are shown from four fixed camera viewpoints, and the respective part is highlighted within the full vehicle view. Additional types of changes will be included in the report in the near future.

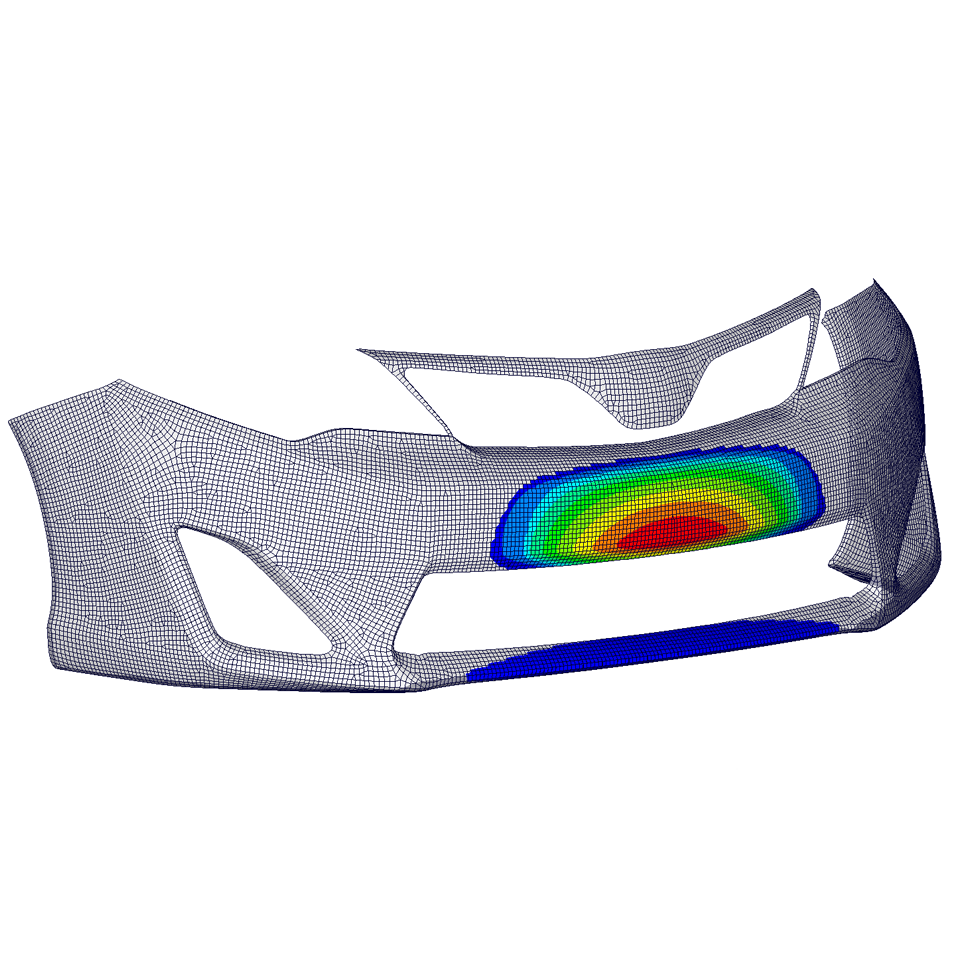

Comparison of changes in user-defined node and element functions

A user-specified function for each node (or element) can be compared between the two models. The detected difference values will be displayed accordingly.

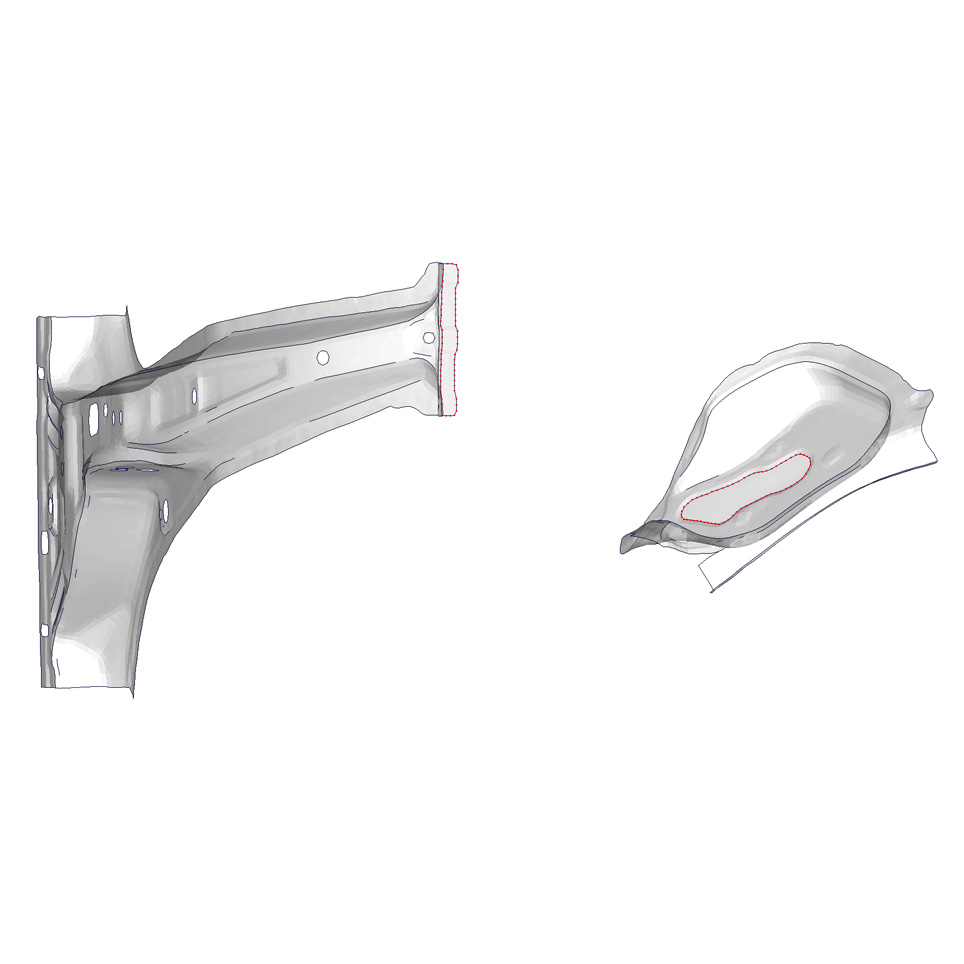

Changes in contours and holes

Changes such as cut, extended, added, and deleted contours can be detected. Similarly, changes in planar holes, such as closed, extended, new, and shortened holes, can be detected.

ASCII comparison

Input files contain additional information not covered by the geometric comparison, for example, transformation blocks, comment blocks, etc. A smart ASCII difference analysis handles such input blocks. Currently, PAM-CRASH is supported, whereas others such as LS-DYNA will be added.