Optimization of industrial processes

An example of a successful material flow simulation project is a process enhancement for BPW Bergische Achsen in Wiehl, Germany. We conducted a simulation study in order to optimize the manufacturing processes in the axle plant.

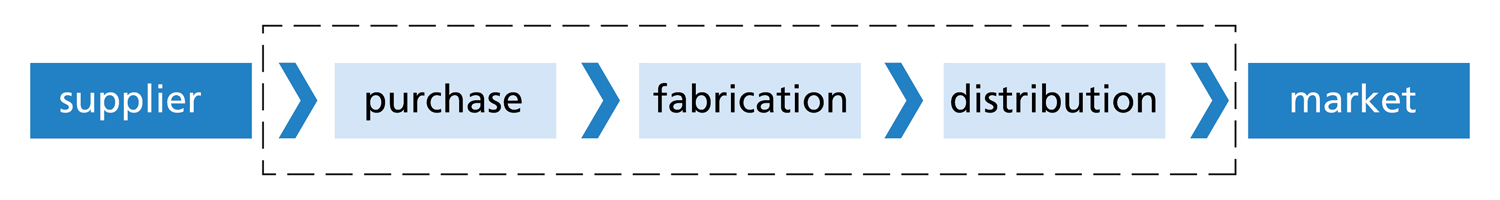

The main problem was a large stock, which led to undesirable capital commitment and required a high effort for order picking. On the other hand it assured on-time delivery even during bottlenecks and breakdowns. Within this project, we aimed at reducing inventory and simultaneously maintaining a high-level adherence to delivery dates. Furthermore, we were asked to conduct sensitivity analyses for exceptional conditions, such as extreme order mix or low material availability, and to develop compensatory measures.

First of all, we modelled the current status in the simulation software Plant Simulation. Based on this simulation, we developed measures for optimizing processes and maintaining performance in collaboration with BPW, such as:

- capacity expansion in certain divisions

- acceleration of clocked machines

- shortening planning intervals

- changing the decoupling point

- common usage of resources

- stronger concatenation of working stations

- globally optimal job scheduling

- variation of the stock’s removal strategy

- elimination of the stock and compensation by innovative concepts

The most promising ideas were implemented in the model, simulated, and evaluated. BPW began implementing selected optimization activities before the project was even finished.

What did we achieve? We managed to reduce inventory considerably without compromising on-time delivery. Furthermore, the project improved inter-divisional communication. After updating the model, it can be reused for future simulations.