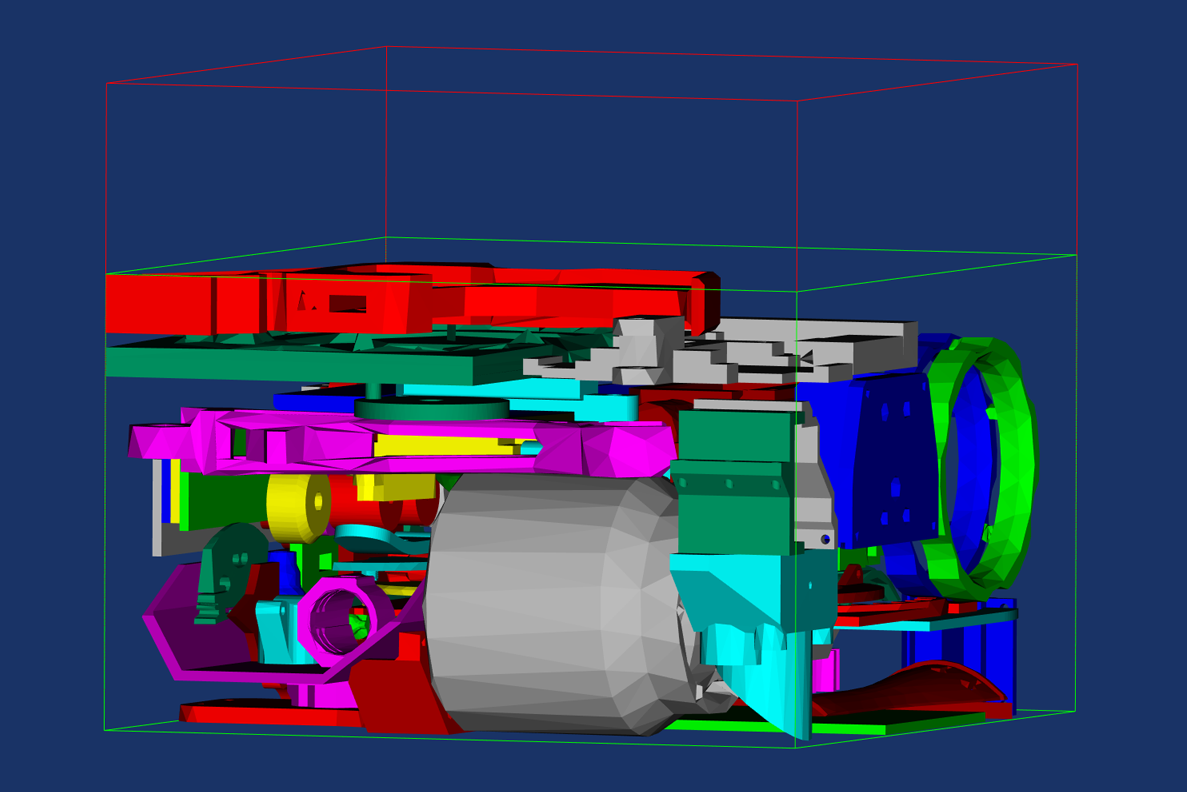

3D Nesting is about arranging objects as good as possible in cuboid containers. The objects themselves do not have to be cuboids, but can be objects of any complexity.

An important field of application is 3D printing, in particular printing processes without support structures such as SLS: here the objects to be printed can usually be placed in the entire print chamber. Clever choice of positions leads to a high volume utilization of the print chamber.

An automated 3D Nesting solution offers some advantages:

- High volume utilization

- Low printing costs

- Reduced printing times

- Consistently high solution quality

- Saves working time compared to manual arrangement

In order to deliver the best possible solution, we use powerful optimization algorithms that draw on decades of experience. Our software products PackAssistant (3D packaging of identical parts) and AutoNester (2D Nesting) are among the world's leading software packages for packaging and cutting optimization.

The 3D Nesting project is currently under development.

You are welcome to contact us, so that we can incorporate also your requirements!