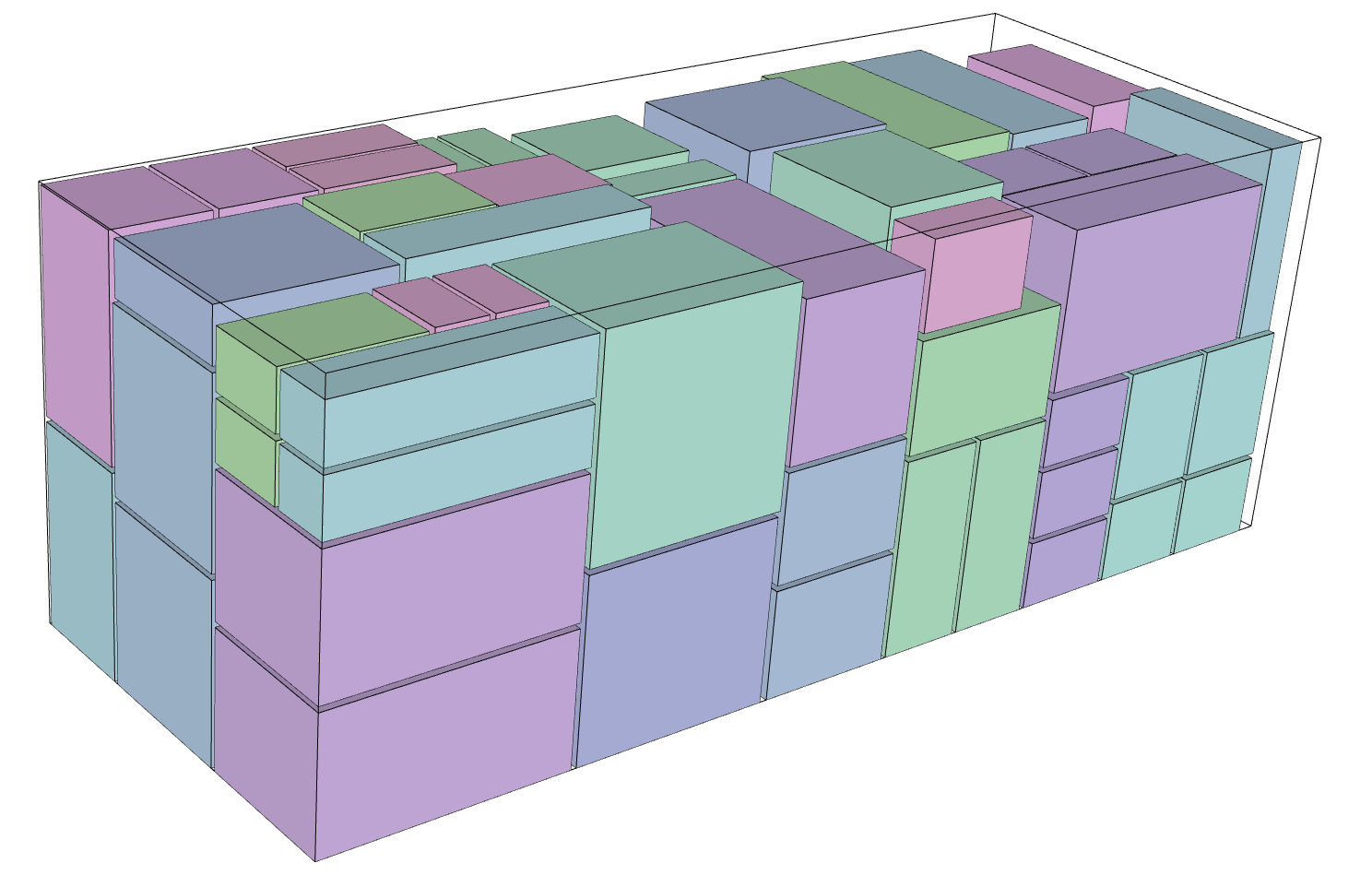

The CuboNester software optimizes the arrangement of cuboid or nearly cuboid parts such as material blocks, boxes, or boards in three dimensions. The algorithm can combine a variety of different parts in one arrangement.

The software is available in two variants:

- CuboNester-C is designed for cutting blocks of material. It can be used for metal, marble, graphite, and foam, among others.

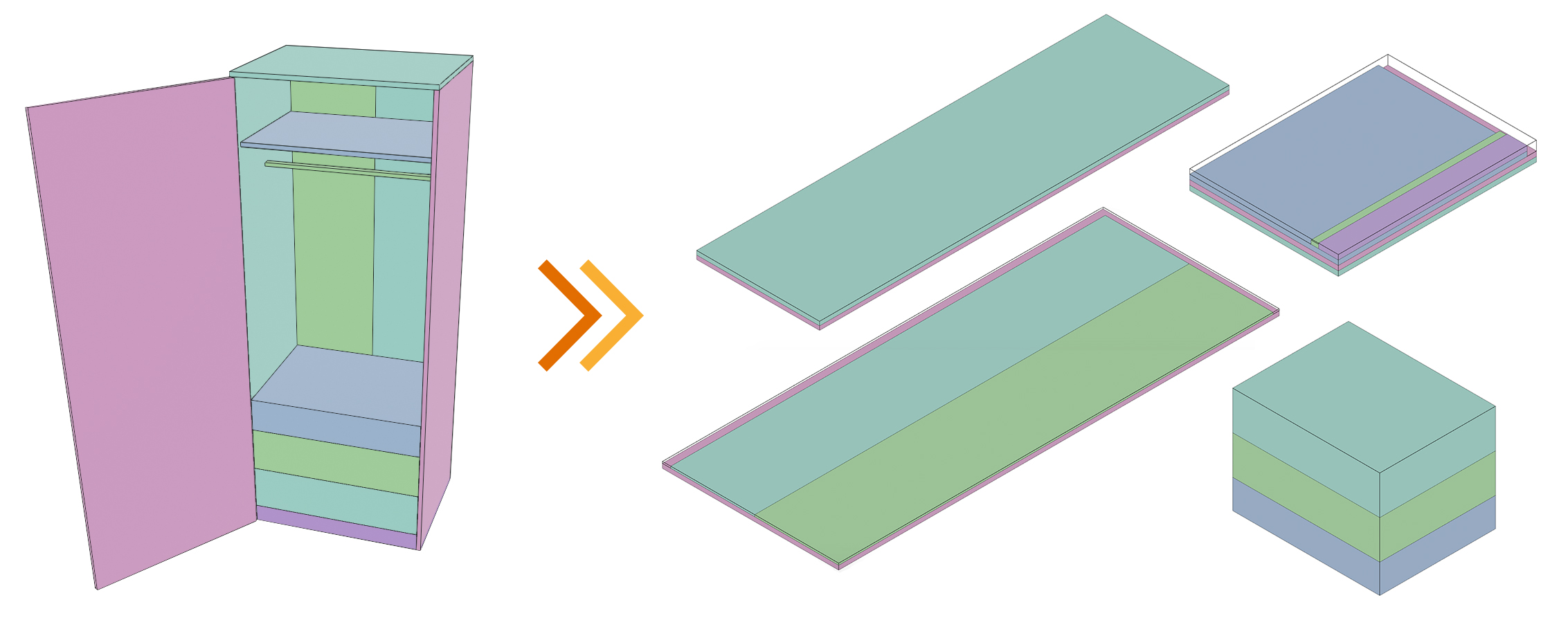

- CuboNester-P optimizes packing, for example of furniture elements into packages.

Other possible applications of CuboNester include packing boxes into shipping cartons for mixed orders in online retail, or pallet and container loading.

CuboNester is still a young product that is tailor-made to meet two customers' needs, for metal cutting and for furniture packaging, respectively. Other customers can license the product and use it with just a few adjustments for these applications. However, we are also looking forward to further developing CuboNester, learning from customers in other areas about the specifics relevant there, and expanding the implementation for these needs.