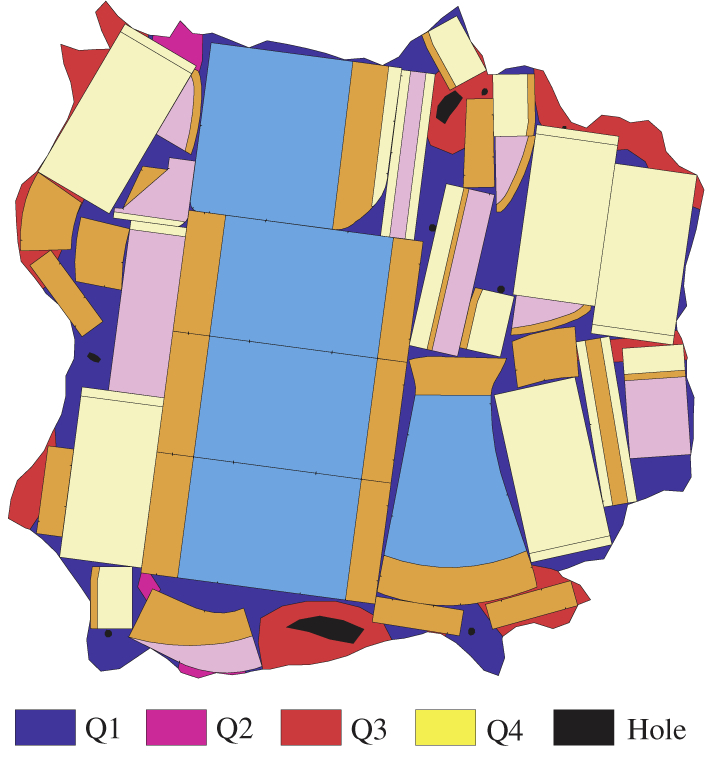

AutoNester-L is a software package for automatic marker making on leather hides. For other materials than leather, we refer to our software package AutoNester-T.

AutoNester-L is widely used in the leather and car manufacturing industry. It is able to nest any set of pieces within a very short time in an optimal way, minimizing wasted material, while taking into account various types of constraints. The efficiency of the markers achieved by AutoNester-L is competitive to experienced human nesters.

The AutoNester-L software is organized as a Dynamic Link Library (DLL) to be used as a developer's tool kit. Developers of CAD-systems can integrate AutoNester-L into their software.

We also offer the creation of custom-made standalone applications for the end user which can be used to create markers from special data formats.