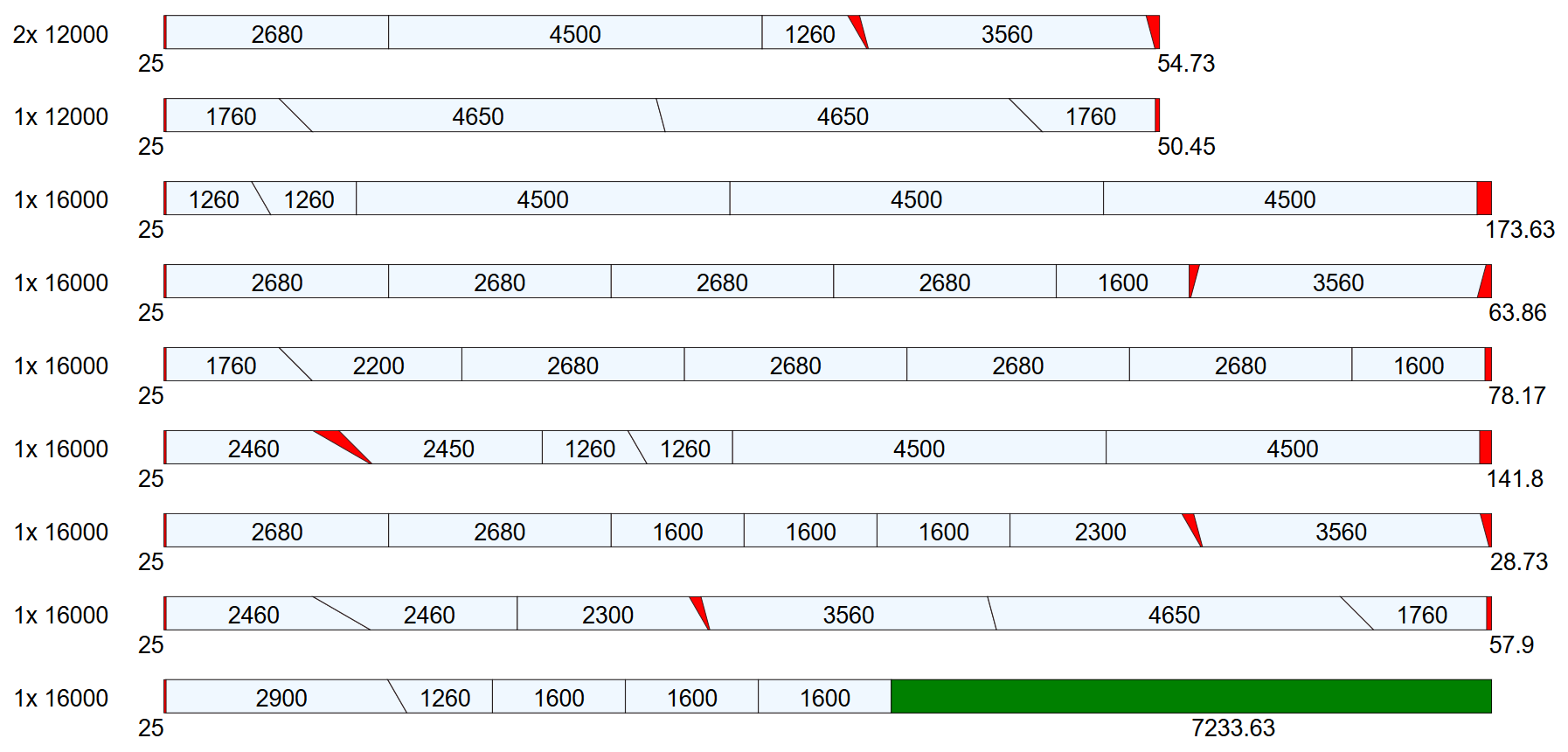

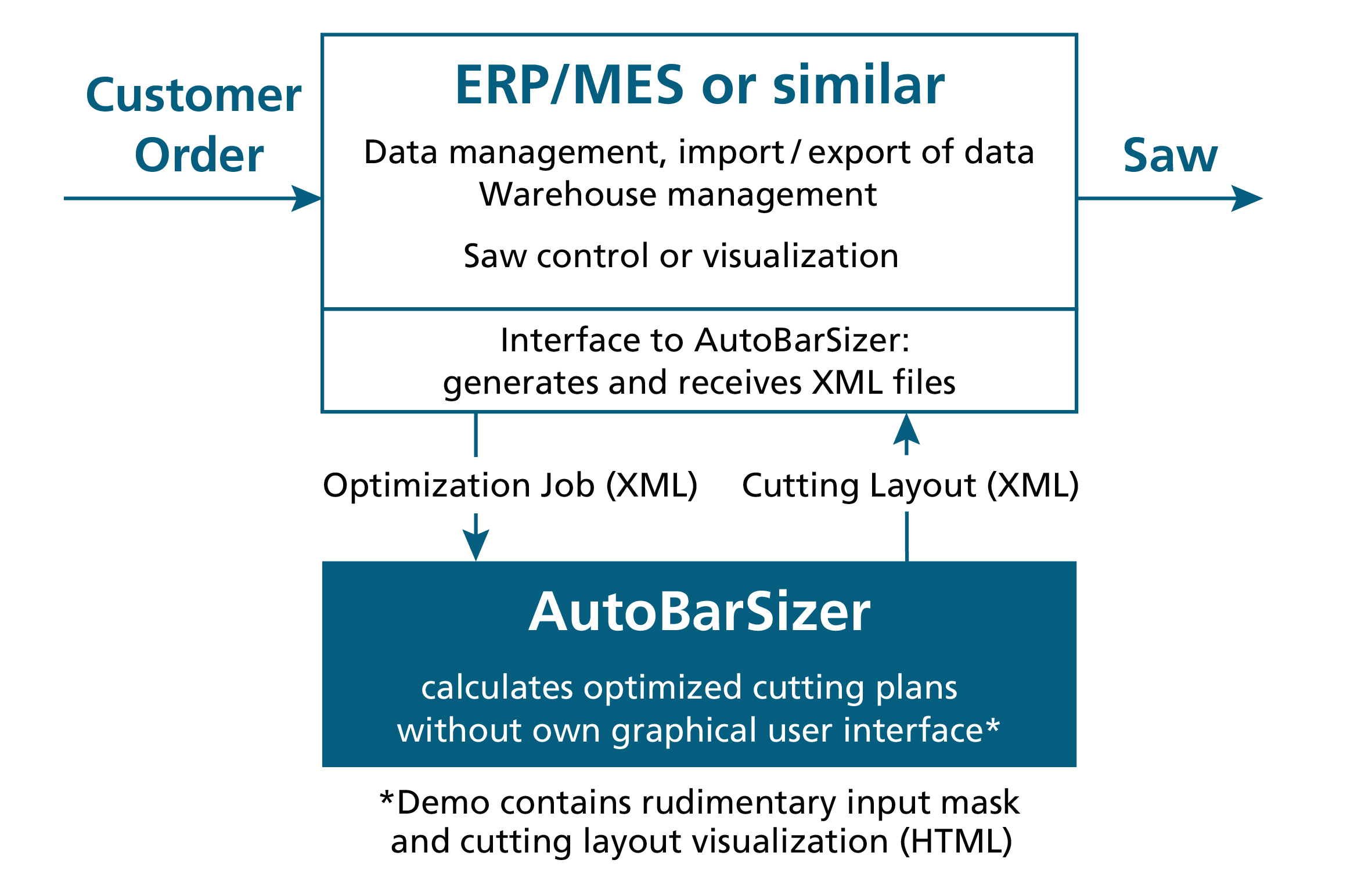

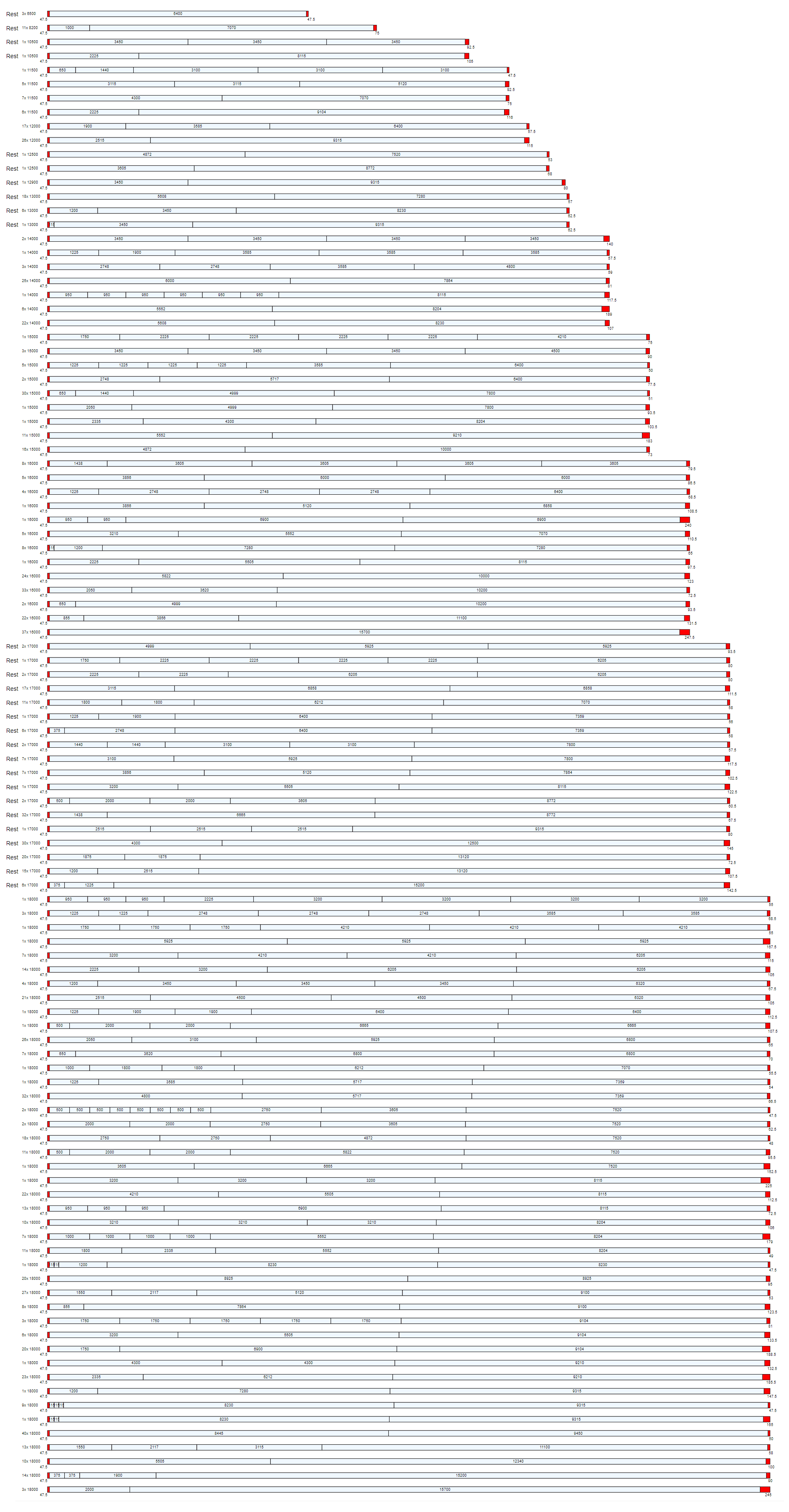

The software AutoBarSizer generates optimized layouts for the cutting of stock items, namely steel profiles (metal beams) and other bars and rods, into shorter pieces. The generated layouts achieve an extremely high degree of material utilization (yield), i.e. the cutting waste is minimized. Furthermore, various configurable constraints are taken into account. The planner can also use different parameters to balance yield and additional organizational effort caused by the reusable remnants produced.

Optimize miter cuts in seconds

When layouts with miter cuts are created, AutoBarSizer also optimizes the interleaving (nesting) of the parts. For this it is sometimes useful to rotate some of the parts. The planner can allow or forbid specific rotations depending on material symmetries and production requirements. AutoBarSizer solves planning questions not only from rolling mills and steel traders, but also from the woodworking industry and manufacturers of material strips of all kinds.

The computation of one common sized cutting layout is completed in a few seconds to a few minutes at the most.