User benefits

In computer-aided engineering (CAE), numerous design changes are applied within the overall design development process until the final model satisfies all design criteria. Each design change has to be analyzed and its influences on the simulation results have to be compared and evaluated. SimCompare is a tool to easily analyze the impact of design changes in terms of data functions.

SimCompare automatically highlights the most relevant parts over time together with local hotspots with respect to design changes. Thus, users are provided insight starting with only two simulations, without the burden of manually determining the differences or the necessity of setting up a simulation database. To document the influences of design changes, a report can be generated which is automatically adjusted for each analysis setup.

Automatic event detection

The SimCompare developers at Fraunhofer SCAI combine mathematics and machine learning to integrate existing application knowledge into data analysis methods. This enables us to provide SimCompare as an important step towards automatic event detection in an overall simulation data analysis workflow. Our tool allows to systematically analyze a design tree and to detect deviations caused by design changes. SimCompare can be used hand-in-hand with the SCAI tool ModelCompare for the identification of design measures realized through model adaptation.

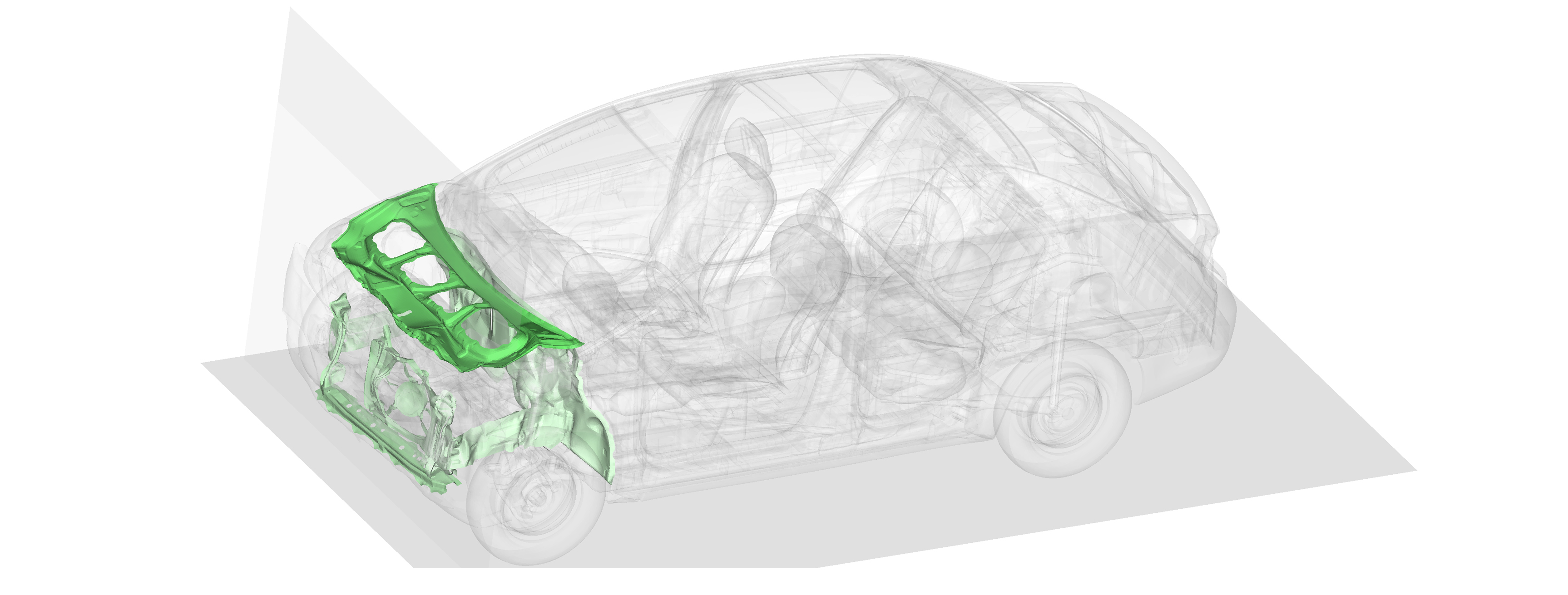

A seamless interface as a plug-in

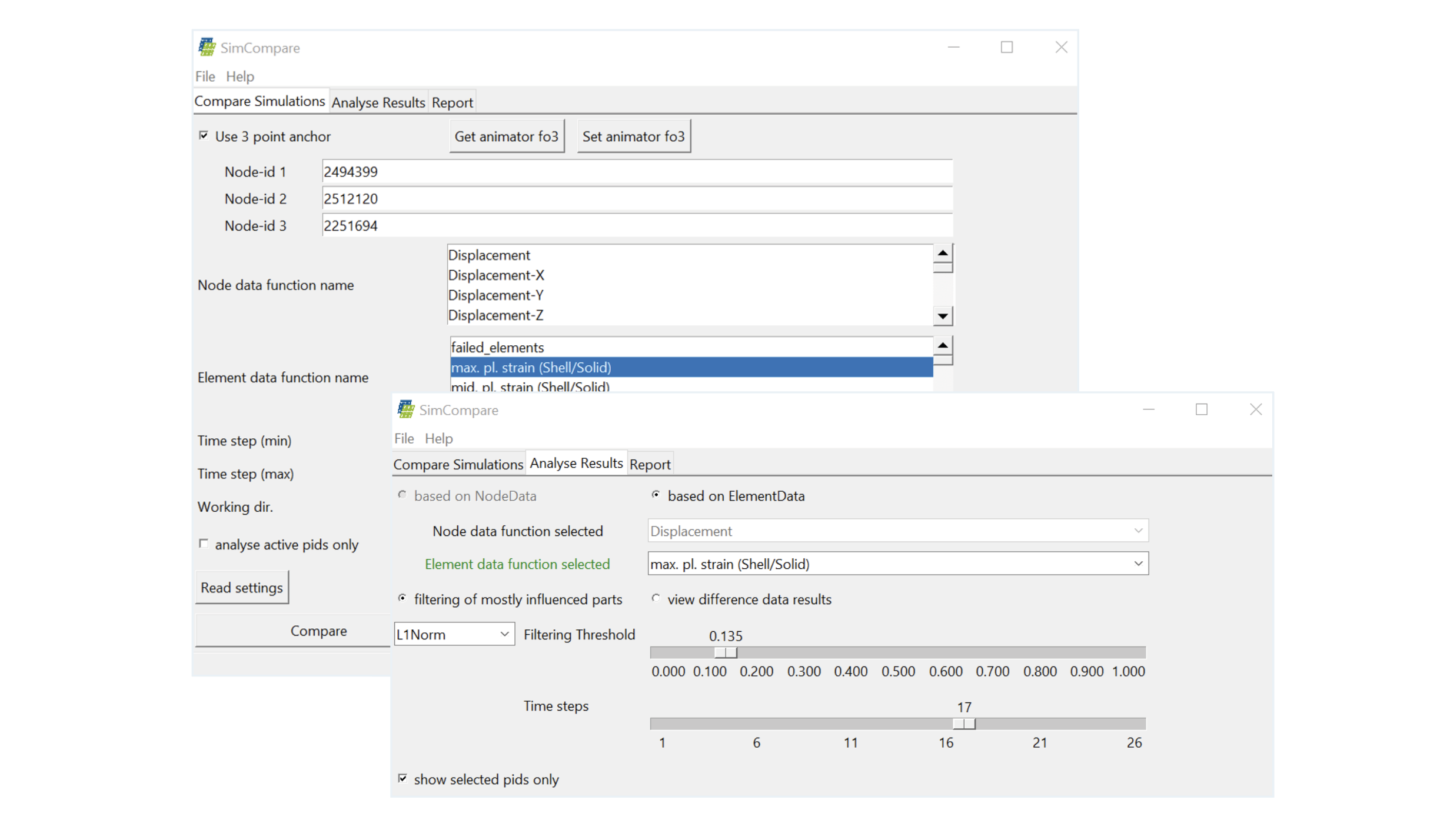

SimCompare is available as a plug-in for GNS Animator or as stand-alone batch tool. Results are visualized directly within Animator. Thus, the CAE engineer needs no additional tool and can easily integrate the SimCompare analysis into a well-established analysis workflow.

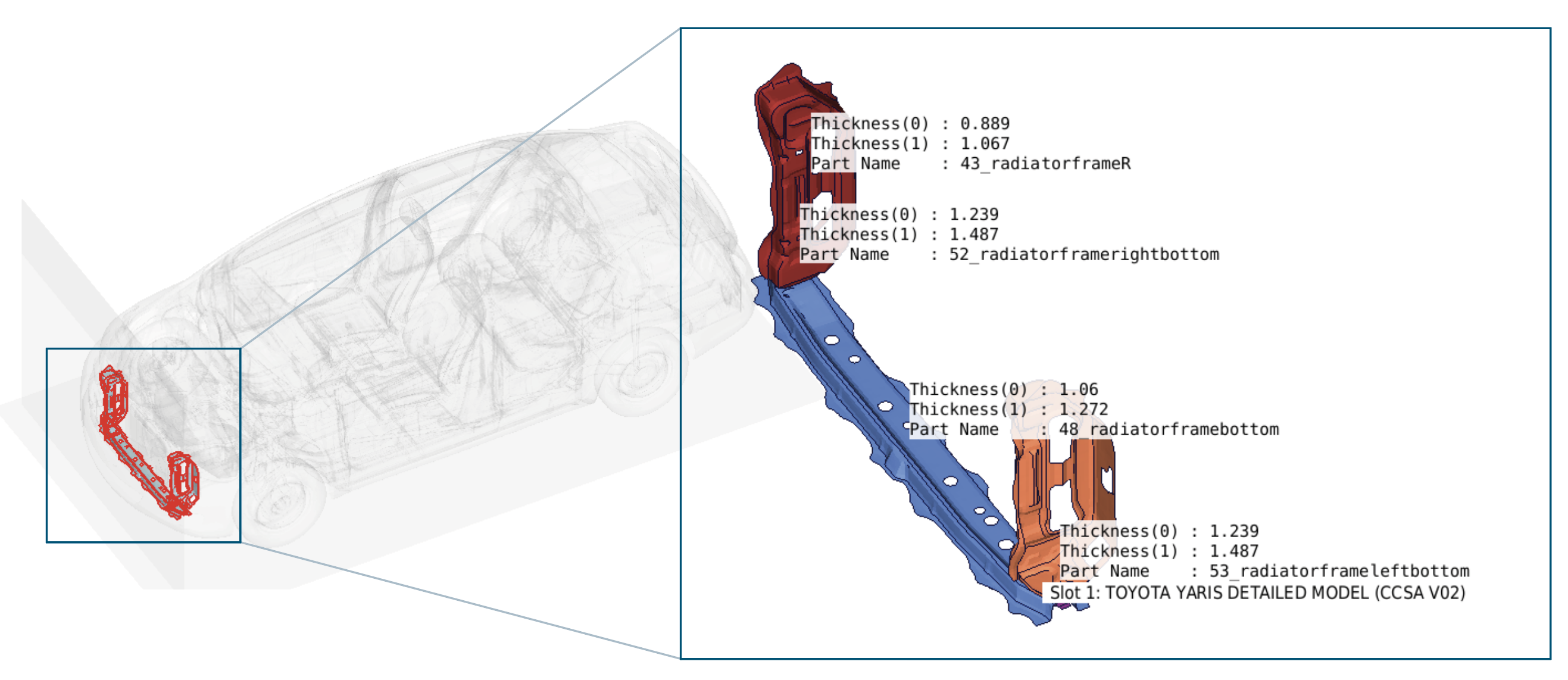

Comparison based on node and element data functions

Arbitrary node or element data functions available in the simulation models (e.g. signed plastic strains, displacements) as well as failed elements can be selected for comparison via the plug-in GUI or by a settings file. Rigid body motion can be extracted for analyzing displacements by setting corresponding anchor points. Thereby, detailed insight into local influences on, e.g., deformations, plastic strains, and stresses, can be evaluated with respect to a certain design change (measure).

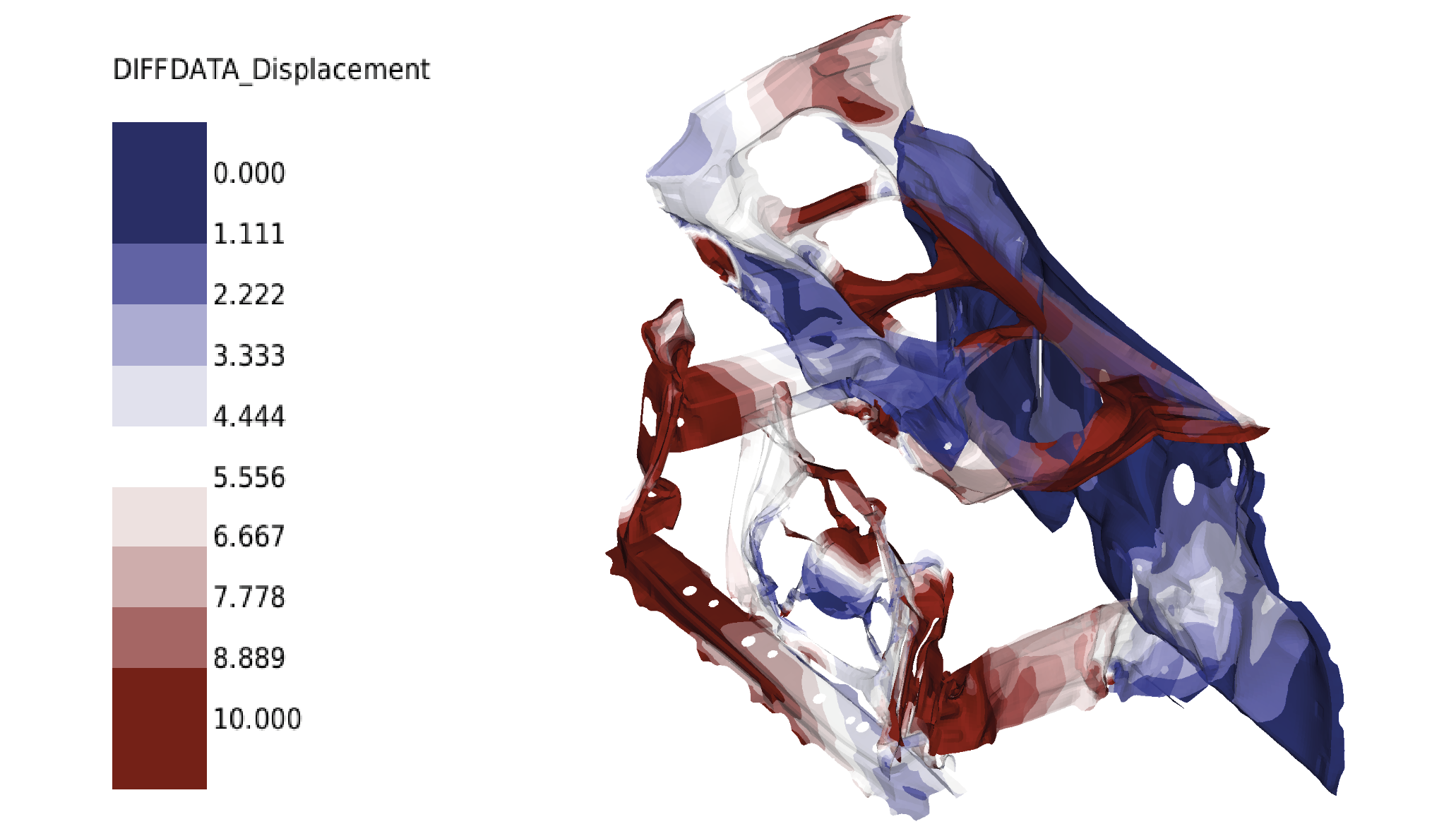

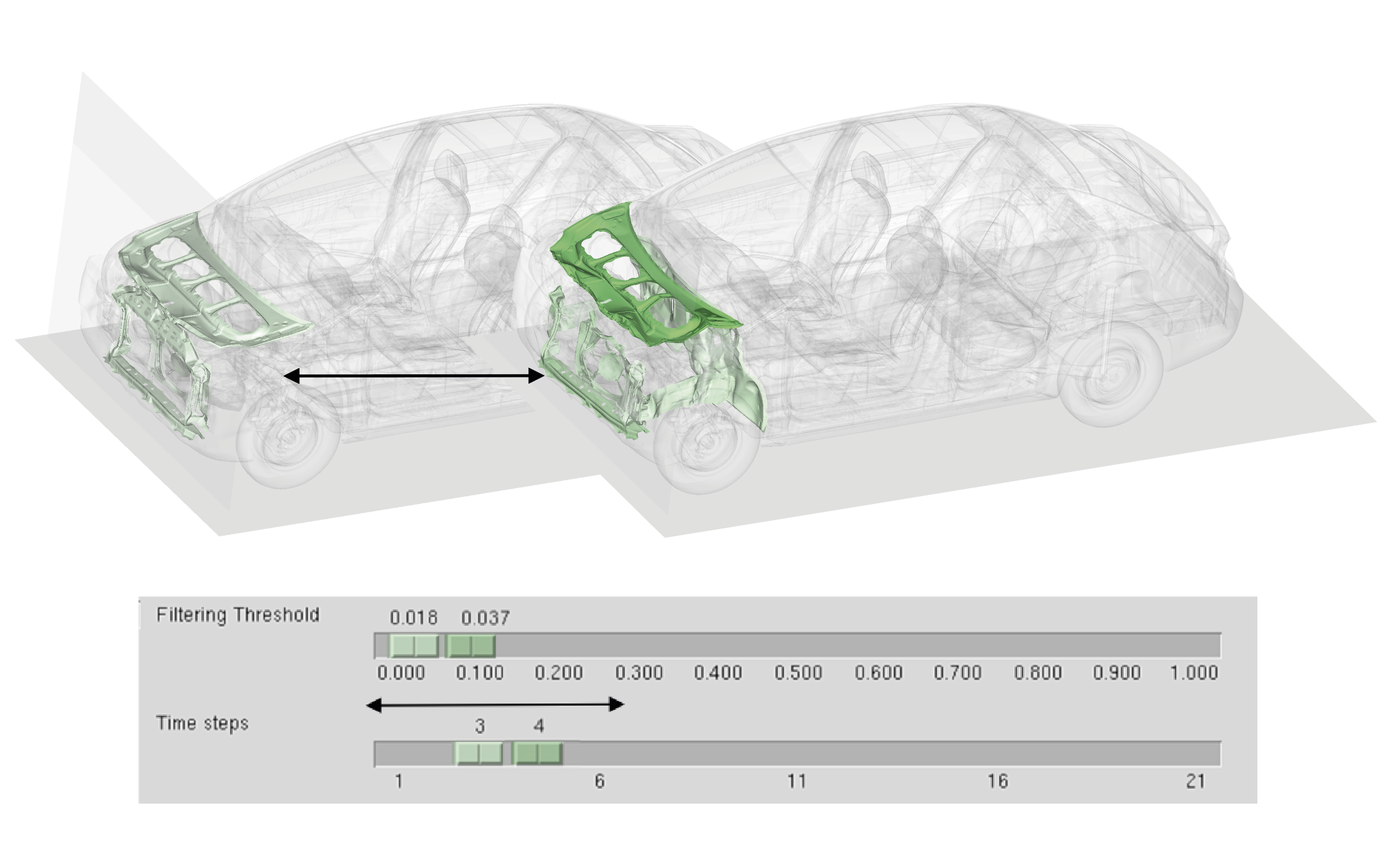

Filtering of the most influenced parts

Differences are computed partwise for similarly discretized FE models. SimCompare uses specialized and well-established mapping techniques known from the SCAI tool ModelCompare. This enables comparisons of models with changed or combined parts. Filtering the most affected parts is supported interactively and automatically enabled in order to detect influences of design changes systematically. Moreover, the SimCompare GUI supports interactively browsing the results over time. Thus, the software informs the user on what events occur locally (part ids and location) and when events occur (time range).

Several metrics for different purposes

Several comparison measures (metrics) are available to focus on global or local influences. On request, these can be extended to other engineering-based metrics, including expert knowledge.

Visualization of local events

SimCompare visualizes deviations on both models, node- and elementwise in deformed state. Exceptionally, the visualization of differences in element failure is realized on the non-deformed mesh with failed elements visible. This feature simplifies the detection of local hotspots. The software shows the whole vehicle or the relevant parts to get an overview of design change impacts.

Automatic report generation / storing of results

Automatic pdf report generation makes it easy to archive analysis results. Additionally, all differences are stored node-/elementwise for loading in the preprocessor tool. The comparison results are stored partwise in structured JSON files supporting further post-processing. Therewith, the integration of results in a Simulation-Data-Management (SDM)-tool of your choice is highly simplified.