Fraunhofer DigitalTPC

The digital twin for thermoplastic composite lightweight construction.

Project Background

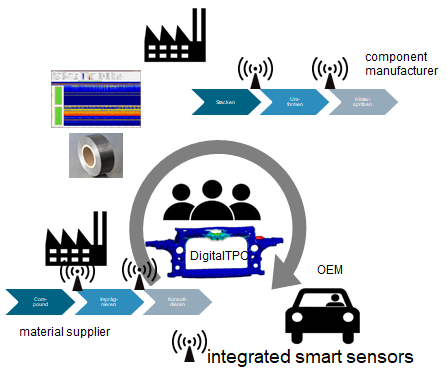

The digital twin for thermoplastic composites (digitalTPC) is intended to demonstrate this potential using the hybrid injection molding technology, which is currently establishing itself on the market and is capable of large series production, in which fiber-reinforced thermoplastic composite (TPC) semi-finished products are continuously formed and back-injected. In particular, the complex and heterogeneous microstructure of the composite material itself and its influence on the manufacturing process in the manufacture of semi-finished products and structural components poses an enormous challenge for process control and quality assurance and requires the complete digitalization of the entire production process.

Project Goals and Partner Contributions

The project digitalTPC aims to comprehensively and holistically consider all sub-process steps, partly taking place at different locations, from the semi-finished product to the component production.

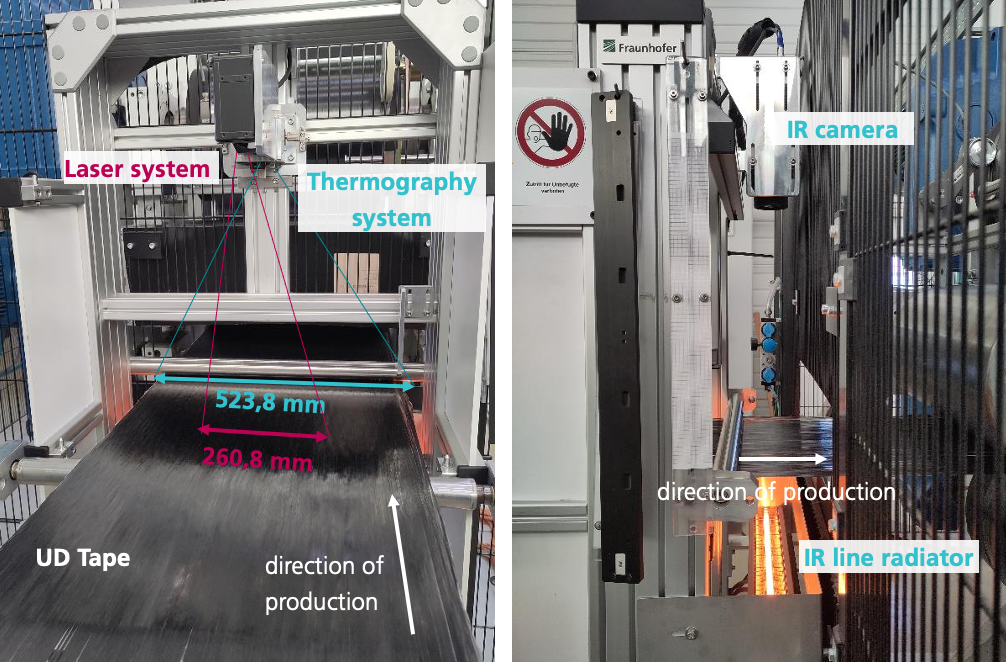

With the help of suitable process-integrated and cognitive sensor technology, selected relevant material, process, and component characteristics (e.g., fiber orientation, pore content, semi-finished product thickness) are to be measured and recorded by the Fraunhofer Institute IZFP, if possible in local resolution throughout the entire real value-added chain.

In addition to material know-how, the necessary production plant technology and tools for demonstrator structures are available at the Fraunhofer Institute IMWS (tape semi-finished product production) and ICT (tape laying, consolidation, and injection molding technology) on an industry-relevant scale. The value chain division between these two institutes reflects the industry-typical relationship between material/semi-finished product manufacturers and component manufacturers.

By applying an ontology, Fraunhofer SCAI organizes data from diverse sources, including sensor, machine, and simulation data. Subsequently, innovative AI-based methods are employed to process the raw sensor measurements. The processed data is semantically linked to form a continuous simulation chain that spans the stages of the manufacturing process. This comprehensive integration provides valuable insights and enables effective visual feedback for engineers and technicians overseeing processes and machinery, functioning as an integral component of the digital twin framework.

Gained Project Innovations

The digital twin project for tape and component manufacturing introduces groundbreaking innovations in data management through advanced ontologies and concepts. It achieves semantic interoperability, creating a holistic digital representation of the manufacturing environment that dynamically integrates knowledge over time. The project uniquely facilitates cross-domain integration, providing a unified framework for machine, simulation, and expert knowledge. Its predictive analytics and optimization capabilities, empowered by ontologies, set it apart by enabling anticipatory maintenance and process optimization. Additionally, the project prioritizes user-friendly interfaces, ensuring intuitive access to complex manufacturing data and promoting broader stakeholder engagement.

Furthermore, the proposed system involves adapting and enhancing a pre-existing deep learning model (advanced Artificial Intelligence model) using transfer learning and continuously updating it with new data over time via incremental learning to detect faults in tapes effectively. This combination aims to make the most of available data while addressing the constraint of limited valid data due to the cost-intensive nature of operating tape machines.

At the end of the project, the project DigitalTPC could demonstrate the use and benefits of its digital twin platform in 4 use case demonstrators

- Optimizing UD Tape Production

- Quality Assessment of CF-PA6 UD Tapes

- Tracking and reducing material irregularities

Further information on the project content, manufacturing applications, sensor concepts, and the virtual platform can be found in the project brochure.

Project Partners

- Fraunhofer Institute for Algorithms and Scientific Computing SCAI

- Fraunhofer Institute for Microstructure of Materials and Systems IMWS

- Fraunhofer Institute for Nondestructive Testing IZFP

- Fraunhofer Institute for Chemical Technology ICT

Advisory Board

- Daimler

- PROSTEP

- Dieffenbacher

- Bosch

Project Details

Project duration: 02/2019 until 01/2022 – 02/2023

Funding Infos: The project was funded by the Fraunhofer Gesellschaft MAVO-Program.