MapUmCra – Improving the transfer (mapping) of simulation data from forming simulation to crash simulation for more accurate failure predictions

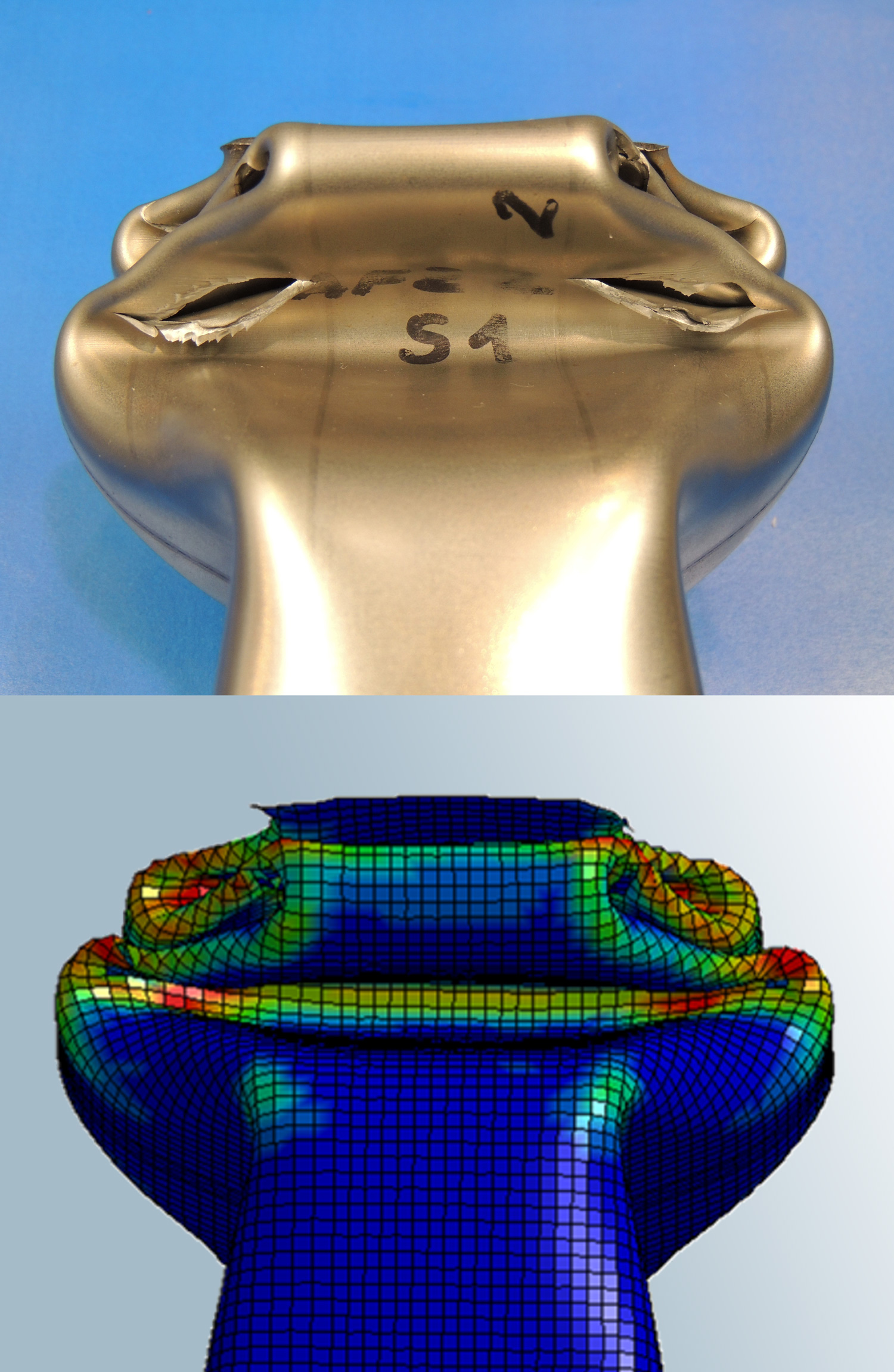

Lightweight design plays a central role in vehicle development, as it helps to reduce both weight and emissions. To achieve this, complexly shaped body components made of sheet metal are used to minimize material thickness. However, during the forming process of these sheets, localized material damage can occur in areas of high internal stress. Such local damage affects the crash behavior of components and poses major challenges for simulation. While these effects are part of real manufacturing processes, they are often insufficiently represented in conventional crash simulations. Although forming simulations can capture such effects computationally, accurately transferring them to crash simulations is so computationally demanding that it significantly slows down industrial development processes. On the other hand, simplified damage models provide only coarse approximations of material behavior, resulting in inaccurate failure predictions and potentially costly design decisions.

The research project MapUmCra aims to accurately and efficiently transfer material damage information from forming simulations to crash simulations. To achieve this, researchers are developing innovative methods to represent, transform, and transfer damage information while accounting for the specific requirements of both simulation types. The objective is to establish a consistent and realistic process chain from sheet metal forming to crash testing. This will enable more reliable failure predictions, reduce the complexity of material modeling, and shorten development times — leading to significant cost savings, particularly for small and medium-sized suppliers.

Fraunhofer SCAI contributes its expertise in multiphysics simulation coupling, data mapping, and interface development to MapUmCra. In doing so, Fraunhofer SCAI lays the foundation for a new generation of digitally connected simulation chains that enable more accurate crash predictions, more efficient development processes, and more sustainable vehicle design.

The project is funded thorugh the Industrial Collective Research (Industrielle Gemeinschaftsforschung, IGF) program of the German Federal Ministry for Economic Affairs and Energy (BMWE). It is supported by the Research Association for Automotive Technology (Forschungsvereinigung Automobiltechnik e.V., FAT).

Project duration: 07/2025 to 12/2027