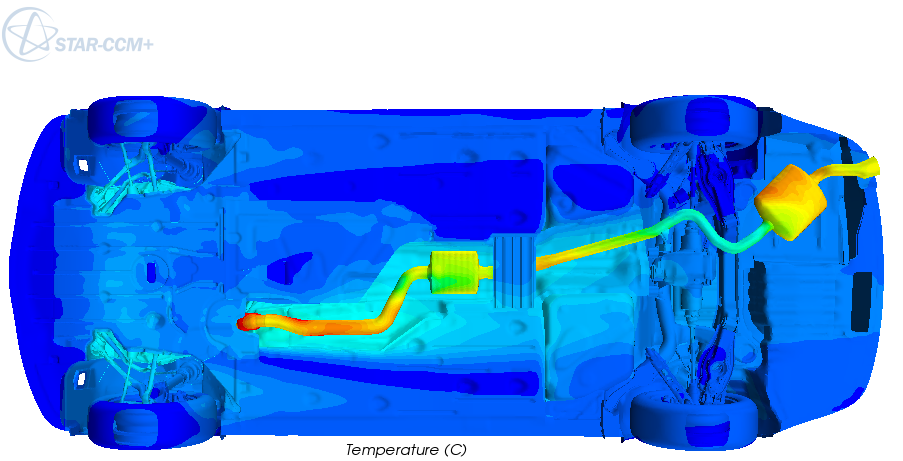

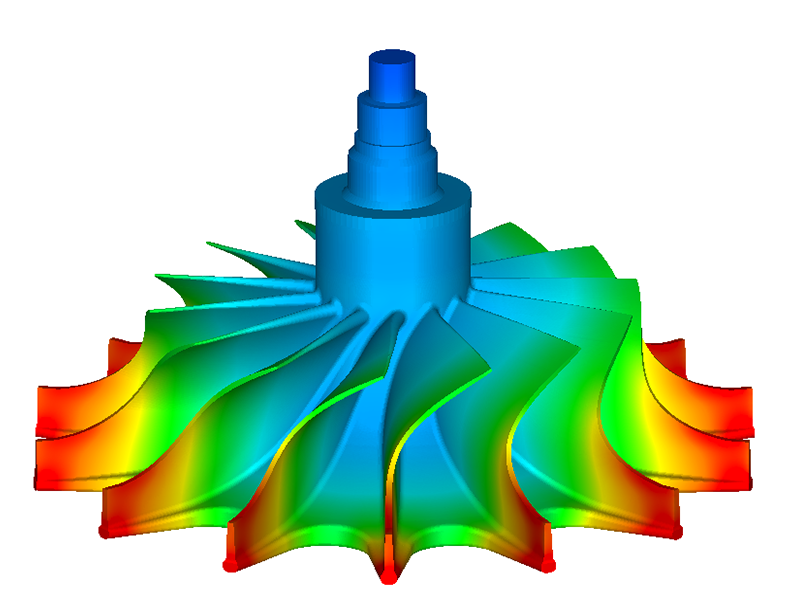

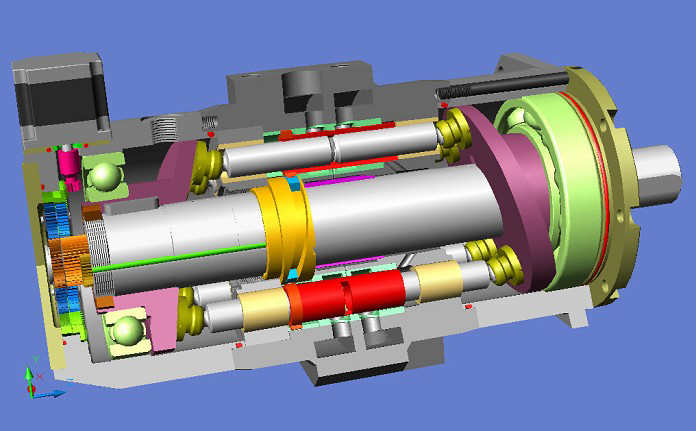

Multidisciplinary simulations become increasingly important to meet the growing demands on the quality of simulation results. Our software MpCCI is the world's leading tool for multiphysics simulations, which require a combination of proven application codes for individual disciplines (flow, structure, acoustics, heat etc.).

The possibilities of use of MpCCI are manifold and relate to very different fields of application.