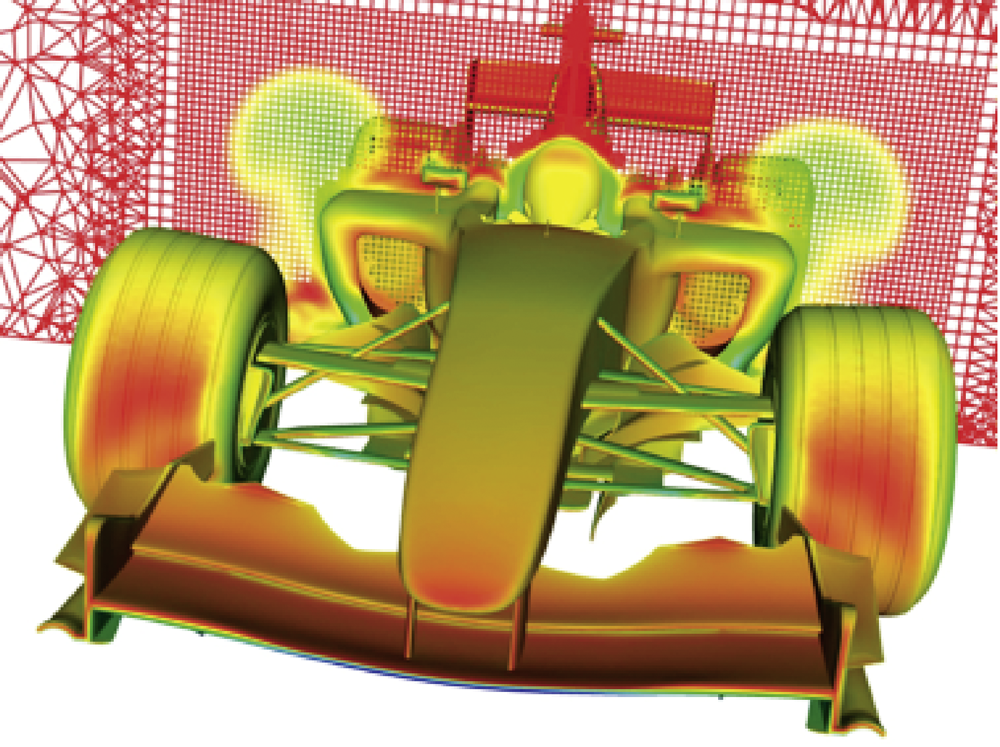

MAGMA accelerates the simulation of die-cast parts

MAGMA GmbH is a specialist in computer simulations of casting processes which become increasingly important in the design of die-cast parts in engines and chassis, for instance. Because casting materials in vehicles are subject to large loads, casting processes must naturally satisfy high standards of reliability and reproducibility. Simulations help deliver detailed information about the behavior of die-cast parts in vehicles – such as possible consequences of residual stress.

MAGMA GmbH uses SAMG to accelerate their simulations. SAMG enables reductions in computing time by factors between two and ten. Thanks to this enormous acceleration, the customers of MAGMA GmbH can simulate more variations in the same amount of time, this way improving the process of optimizing the quality of their cast products.